Introduction: The Quiet Force Behind Modern Design

While AI and 3D printing dominate headlines, another innovation has been steadily transforming architecture and construction: Building Information Modeling (BIM). Unlike flashy technologies, BIM drafting and modeling services quietly redefine how architects, engineers, and contractors work together.

At Moksh CAD, we integrate Revit shop drawings for stone cladding, MEP BIM modelling, and fabrication-ready CAD drawings into collaborative workflows—bridging the gap between design, takeoffs, and construction execution.

What Is BIM and Why Is It Revolutionary?

BIM is more than digital drawings—it’s a data-rich 3D model combining geometry with information:

- Materials, costs, schedules, and lifecycle data

- Linked countertop estimation and takeoffs

- Integrated slab layout optimization services and CNC-ready shop drawings

Unlike traditional CAD, BIM enables clash detection and construction-ready simulations before problems occur onsite.

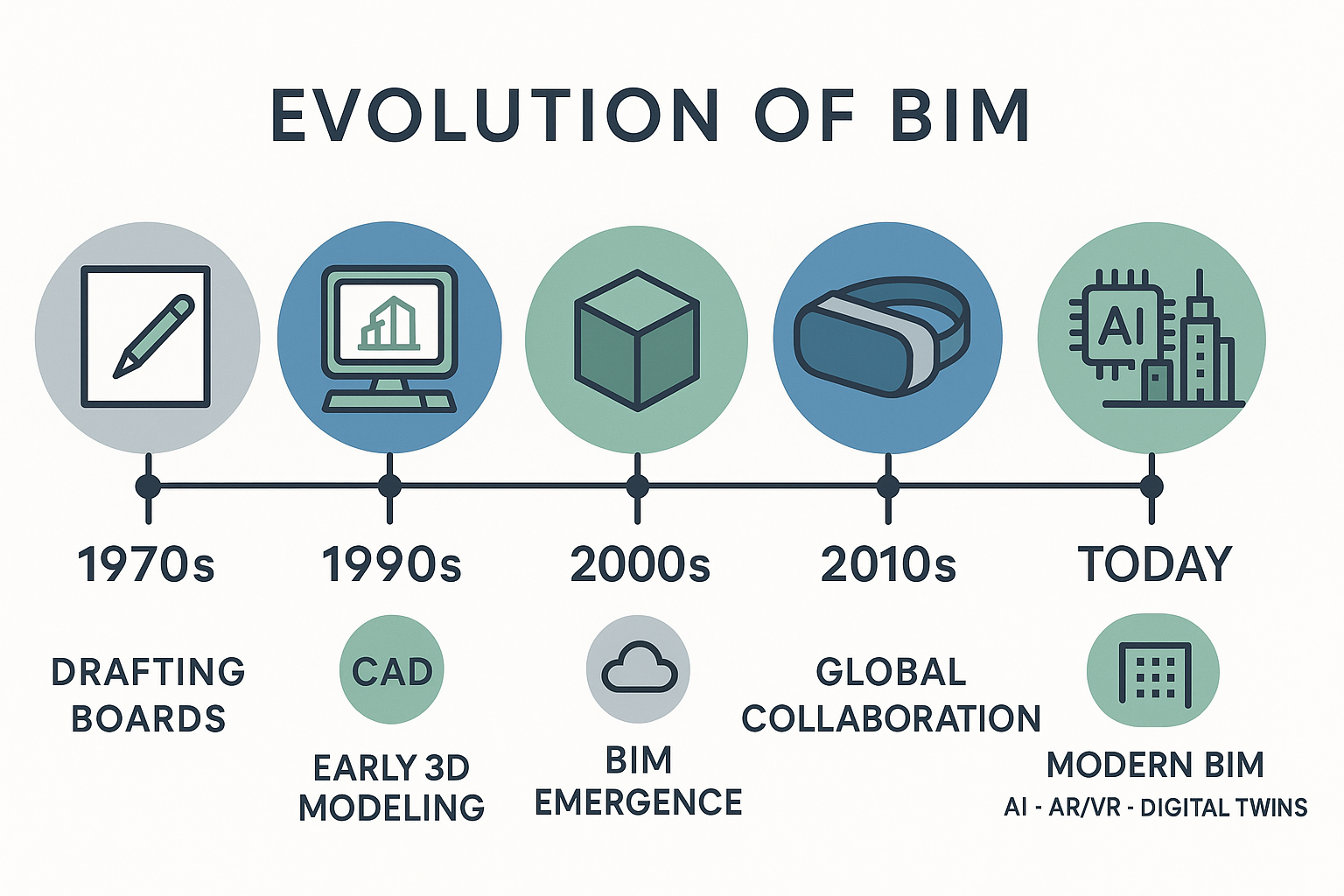

From Drafting Boards to Digital Brains

- 1970s–1990s: CAD replaced manual drafting.

- 2000s: BIM evolved, enabling parametric shop drawings and data integration.

- Today: BIM integrates cloud, AR/VR, and digital twins with CAD outsourcing for fabricators—creating intelligent, adaptable ecosystems.

Explore our CAD 2D/3D Drafting Services.

Core Benefits That Make BIM a Game-Changer

1. Data-Rich Modeling

- BIM is an information hub, embedding metadata about materials, costs, and performance.

- Supports informed decisions at every stage of design, fabrication, and operation.

2. Clash Detection and Coordination

- Detects conflicts between structural, electrical, and mechanical systems.

- Saves costs by preventing rework before fabrication.

3. Lifecycle Management

- Models extend beyond design into operation and maintenance.

- Facility managers benefit from fabrication-ready drawings for installers and digital twins.

4. Cost & Time Efficiency

- Automated fabrication takeoff services improve accuracy.

- Onshore, offshore, and hybrid CAD outsourcing models help maintain schedules and budgets.

Sustainability with BIM

- Simulate energy performance to optimize efficiency.

- Reduce slab waste with nesting optimization for stone slabs.

- Test multiple design scenarios for greener buildings.

Collaboration & Standards

- Shared stone shop drawings service for contractors via cloud platforms.

- Consistent adoption with ISO 19650 standards.

- 24/7 remote CAD support for fabricators ensures global coordination.

Barriers to Adoption

- Steep learning curve for traditional drafters.

- Software + training costs.

- Resistance to change from legacy firms.

Yet, with public projects increasingly requiring BIM, adoption is accelerating.

The Future of BIM

- AI & Generative Design: Automated optimized layouts.

- AR/VR: Immersive visualization for client approvals.

- Digital Twins: Live data for predictive maintenance.

See how our MEP BIM Modelling connects future-ready workflows.

Real-World Impact

BIM is proving itself:

- Lower rework with quality-checked CAD for stone fabricators.

- Faster timelines via scalable CAD teams for fabricators.

- Commercial stone shop drawings for high-rise facades that meet compliance and sustainability goals.

Conclusion: The Silent Revolution Everyone Should Hear

BIM isn’t just software—it’s a cultural shift. From CNC toolpath programming to Revit shop drawings and fabrication-ready CAD resources, BIM ensures projects are efficient, sustainable, and future-ready.

Ready to transform your next project? Let’s Talk about dedicated CAD resources, hybrid outsourcing models, and BIM-powered collaboration with Moksh CAD.